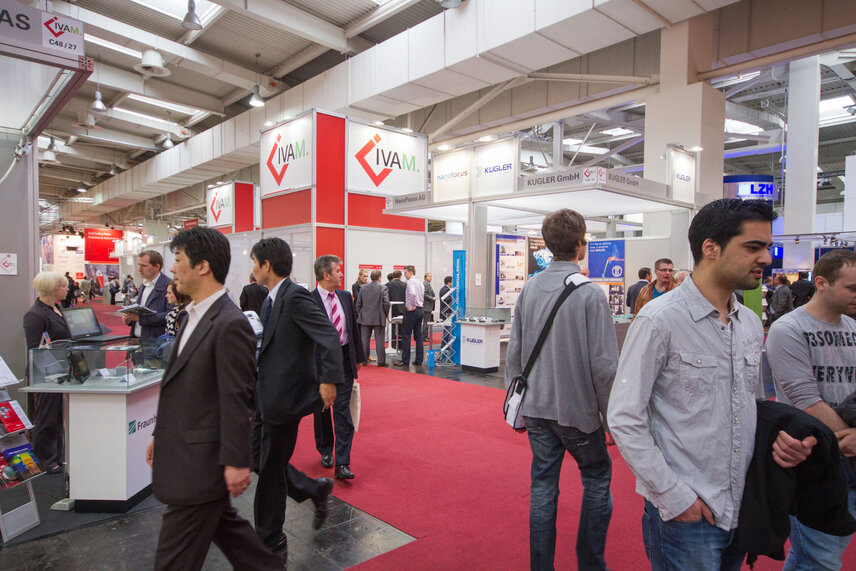

From April 13.-17, 2015, the world’s leading industry trade show HANNOVER MESSE showcases the latest trends and innovative technologies along the entire value chain. The IVAM Microtechnology Network will pool Key Enabling Technologies of the future at a joint booth in Hall 3. These technologies will make it possible to greatly increase efficiency and speed of industrial products and processes while at the same time reducing cost. End users looking for high-precision high-tech solutions will find everything they need at the IVAM Product Market “Micro, Nano & Materials”.

IMT Masken und Teilungen is the specialized partner for the development and manufacture of flow cells and biochips in glass, as well as for components for microfluidics, electrodes, gratings with wave guides and other optical coatings for many detection, sequencing and sensing applications in life science and biophotonics. IMT is able to fulfil the complex technical requirements by applying their expertise in microstructuring and miniaturization to meet the need for continuously smaller and more complex microstructures and optical coatings. The production site using fully automated production equipment from the semiconductor industry enables IMT to achieve cost-effective manufacturing of large quantities with high reproducibility. This means that the use of glass components now becomes possible in applications where it was previously too expensive. IMT supplies customized microstructures on and in glass and in metallic and dielectric layers on substrate sizes of up to 200mm in diameter as micro channels, electrodes, waveguide grating and other optical layers.

ISRA VISION / 3D-Shape brings two new highlights to the HANNVOER MESSE: a revised product family of high precision white light interferometers and a completely new method for high speed measuring of reflective surfaces. The tried and tested KORAD3D white-light interferometer have received a thorough ergonomy and ease-of-use optimization pass. The revised product line offers significantly easier access to complex data and analyses, all with the intuitive interface of a touch panel display. The new high speed 3D sensors of the SpecGAGE3D line measure and evaluate reflective surfaces in seconds in all three dimensions. These innovations enable efficient quality assurance and process optimization.

LIMO Lissotschenko Mikrooptik GmbH’s diode laser systems are opening up new possibilities for plastics welding in the automotive sector, in medical engineering and in many other industries. The clear advantages of the LIMO laser materials processing solutions include improved machining results as a result of flexible, customized beam shaping, process reliability through using intelligent machining tools and energy-saving laser modules. At HANNOVER MESSE, LIMO will also be showing line lasers and special beam-shaping systems that generate very narrow, uniform lines for large-area surface treatment. These are ideally suited for tempering and laser lift-off processes used to manufacture flexible displays or OLEDs, for example. Other material engineering processes include crystallization, sintering and activating charge carriers.

Micrometal GmbH specializes in industrial etching of highly accurate metal micro-components. The etched parts comply with tightest specifications and are always clean, burr- and stressfree. Their in-line etching process makes it possible to produce large volumes cost effectively - as endless bands (called reel-to-reel process). Micrometal is an ISO/TS 16949 and EN ISO 13485 certified company. The most complex product shapes can be etched out of metal with tightest tolerances. Design options for photo etched parts are almost unlimited at Micrometal, as wet etching processes provide the customer with far more freedom than alternative technologies like stamping, electro-forming or laser cutting.

Nanofocus AG realizes non-destructive measurement technologies are becoming increasingly important in research and industry. Through non-contact optical surface measurement technology, relevant 3D surface texture characteristics for an effective quality assurance can be determined. NanoFocus offers three lines of confocal-based 3D measurement systems for a broad range of non-contact measurement tasks on nearly all surfaces: the μsurf 3D metrology systems, the μscan 2D/3D optical profilometers, and the μsprint 3D in-line sensors. They enable roughness measurements conforming to DIN EN ISO norms, defect detection, as well as determinations of form, waviness, volume, step heights, and further relevant surface characteristics. The accompanying software offers nearly limitless opportunities for evaluation.

The supraregional network

NanoMat located with its managing office at

the Karlsruhe Institute of Technology was founded in 1997 as one of the first nano competence centers in Germany. Comprising partners from industry and academia it initiates and conducts application-oriented R&D projects along the innovation chain. NanoMat offers dedicated symposia on key topics of nanotechnology and provides PR activities, eg. exhibition presence and newsletter.

At HANNOVER MESSE, the IVAM Microtechnology Network will demonstrate the advantages it offers to high-tech suppliers. With IVAM’s help, companies and institutes from all over the world open up innovative markets and set new standards. IVAM accelerates the transfer of innovative ideas into profitable products. Apart from technology marketing, IVAM’s activities include lobbying, market research, project management as well as accessing international markets.