Favorite (5)

Favorite (5)

Microelectronics has a long tradition at COMPAMED. Every year, companies and institutes from all over the world present new miniaturized products, necessary accessories for reliable operation or inform about sophisticated services in the field of R&D.

Here is a brief insight into the portfolio of exhibiting companies and institutes of the IVAM area at COMPAMED in the field of electronics and accessories for high-precision microelectronics.

AEMtec GmbH, a leading European provider of hybrid micro and optoelectronic applications, develops, qualifies and produces complex modules for the medical sector, such as wearables, handhelds, diagnostics, medical equipment, imaging and acoustic systems and laboratory diagnostics.

AEMtec meets high quality assurance and is ISO 13485 (Medical) certified. Innovative technologies like UBM, SBA, Dicing, COB, FC, SMD or Box-Build reduce delivery times and costs.

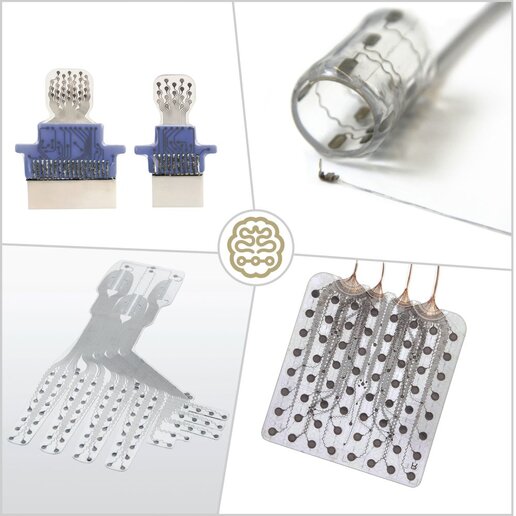

The CorTec GmbH enables communication between the nervous system and artificial intelligence. CorTecs Brain Interchange technology is an implantable system that records and stimulates brain activity chronically for long-term use.

As a closed-loop system, it can control stimulation online, based on brain activity recorded simultaneously.

In addition, the company is providing single individual components like flexible electrodes or high-channel encapsulations together with electronics and software. They are characterized by the same set of features: high precision, high flexibility in design and high number of channels.

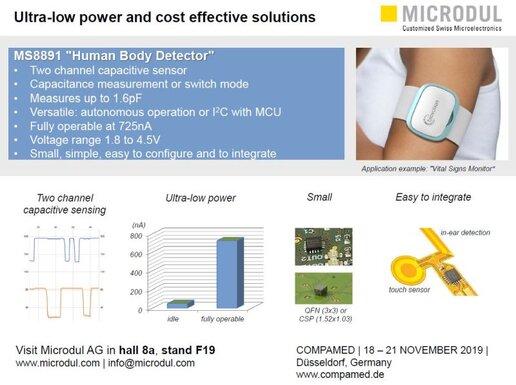

Microdul AG specializes in high-quality microelectronics. The company's three business lines are customized modules, thick-film and mixed-signal Iow-power ASICs.

With ISO 13485, the company's core competence is in producing cutting-edge micro miniature modules for medical and industrial applications, such as implants, hearing aids or modules for use in healthcare.

SMT ELEKTRONIK GmbH is an expert for the development, production and the full service of electronic assemblies and devices.

Customers could enter the project on every step of the process chain with the help of the specifically created EMS-Preflight method.

SMT ELEKTRONIK works from the very beginning in series – ranging from design and series production to a reliable service. EMS-Preflight evaluates simultaneously the four key factors of the series-reliable assembly production and navigates the customer’s product idea precisely into the market.

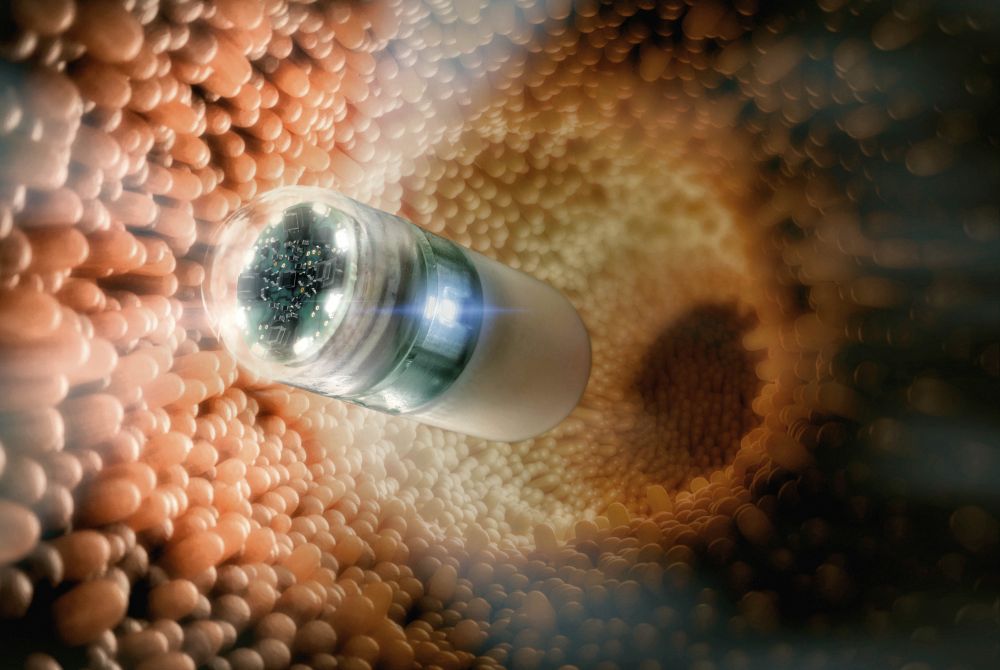

The Fraunhofer Institute for Reliability and Microintegration IZM works on advanced integration techniques for innovative medical devices.

Applications range from ultraminiaturized implants, cardiovascular diagnostic catheters to wearables for multisensor monitoring. The researchers use high-end processes like flex circuit integration, stretchable electronics and wafer level high-density integration to enable next generation medical electronics.

Sensors and wireless interfaces complement these technologies. Risk analysis and biocompatibility assessment ensure compliance with the Medical Device Regulation.

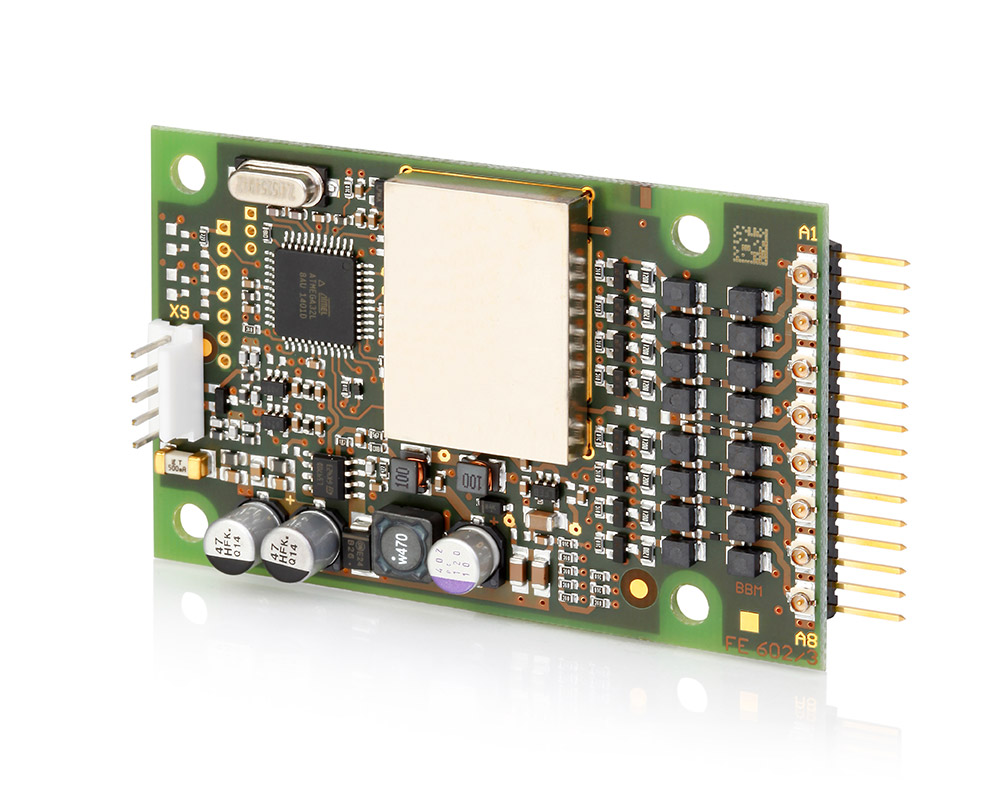

FEIG ELECTRONIC develops and manufactures RFID components for installation in medical devices and for process optimization in hospitals as well as hybrid barcode systems and wearables for material supply and e-Kanban.

For integration into respiratory or in-vitro diagnostic devices numerous RFID modules are offered, which clearly identify samples, reagents or attached accessories. To optimize processes in hospitals, RFID readers are used for the identification of beds, textiles or medicines, as well as patients undergoing various treatment steps.

Optiprint introduces new products in the field of flex and rigid flex PCBs at COMPAMED 2019.

These include flex- and flex-rigid PCB's, ultra-thin rigid multilayer PCBs for interposer applications (chip-packaging solutions), ultra-fine line structures line/space < 25 µm, printed circuit boards with ticer foil, thin film resistor technology or FaradFlex capacity foil, DIG, EPIG or ISIG, as alternative surface to ENEPIG. These surface treatments are particularly suited for gold wire bonding.

LEMO is the acknowledged leader in the design and manufacture of precision custom connection and cable solutions. LEMO's high quality push-pull connectors are found in a variety of challenging application environments including medical, industrial control, test and measurement, audio-video and telecommunications.

The company has been designing precision connectors for seven decades. Offering more than 75,000 combinations of product that continue to grow through custom-specific designs, LEMO and its affiliated sister companies currently serve more than 100,000 customers.

Northwire, Inc. is a responsive partner for developing and manufacturing customized technical cables, coil cords and complete interconnectivity solutions. The company offers technical cables tailored to unique application.

Cables are often subsequently processed in a product development project. In the case of deadlines, complex cable specifications or official approvals may be overstretched. Northwire assists with custom cable projects to resolve any connectivity issues.

We cordially invite you to visit the IVAM joint pavilion “High-tech for Medical Devices” in Hall 8a. On 700 sqm of space, 55 companies present their solutions for medical technology. The IVAM exhibitor catalog includes all profiles of this year’s exhibitors and will help you plan your visit in hall 8a. The file is available at https://ivam.de/events/compamed_2019?lang=en in the download-section on the right-hand side.