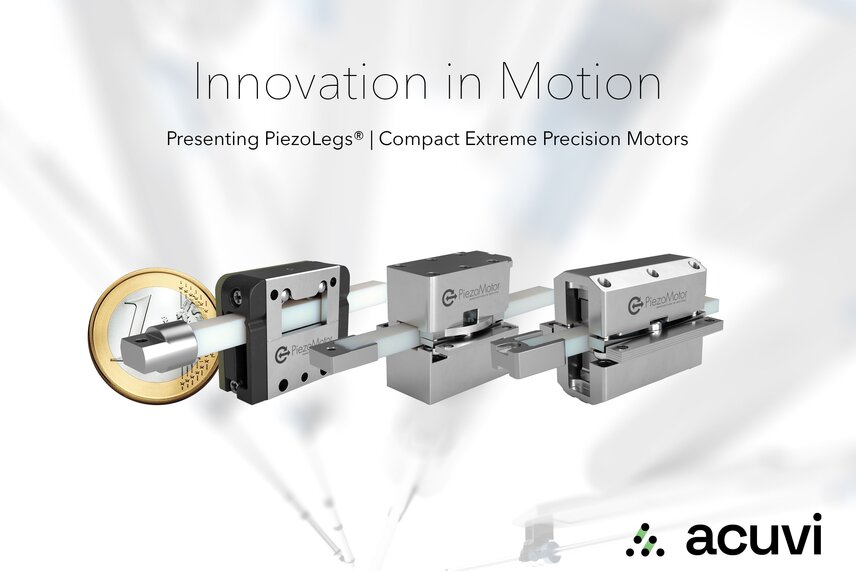

In a ground-breaking development poised to revolutionize the medical devices market, Acuvi proudly brings its 20 years of motor development experience to the MedTech industry: a state-of-the-art LEGS piezo motor family, engineered and manufactured in-house to set new industry standards. With unparalleled features such as the best size-to-force ratio, an exceptional stroke length of up to 10 cm with sub-100 nm resolution, compatibility with magnetic environments, ease of integration, an integrated auto-holding brake, and non-backlash movements, this motor heralds a new era of precision and reliability in medical device design and functionality.

Acuvi’s LEGS piezo motors boast an exceptional size-to-force ratio, making it the ideal choice for applications where space is at a premium. The compact design of these motors ensures optimal performance without compromising on power or precision. With an astonishing stroke length of up to 10 cm and a resolution of below 100 nm, medical devices equipped with our piezo motor offer unprecedented precision. This level of accuracy is critical for applications such as surgical robotics, ensuring surgeons can perform intricate procedures with utmost confidence.

The piezo motors are designed to excel in magnetic environments, making it the perfect choice for MRI-guided medical procedures and diagnostics. Their ability to operate seamlessly in such conditions enhances the versatility of medical devices and opens up new possibilities for diagnosis and treatment.

Acuvi’s LEGS piezo motors are engineered for ease of integration into a wide range of medical devices. Their integrated features reduce the need for additional components, which simplifies the design process, reducing development time and costs. Our team of engineers provides excellent integration support for seamless product development.

Safety is paramount in medical devices, and our piezo motors incorporate an integrated auto-holding brake. This feature ensures that the motor stops immediately when required, preventing unintended movements and minimizing the risk of accidents during critical medical procedures.

The motor’s non-backlash movements guarantee smooth and precise motion control, eliminating the play or jerking commonly associated with traditional motors. This enhances patient comfort and overall procedural accuracy.

Hall 8a, booth H19.3

The SensorNetwork³ Symposium brought together experts from industry, research and politics at the DASA in Dortmund in mid-January to discuss …

The first Chemnitzer Seminar of the year 2025 is entitled “Test and Reliability Solutions – new opportunities for electronic components …

IVAM is part of the Skills4Chips project, a groundbreaking initiative supported by a €12 million investment over the next four …