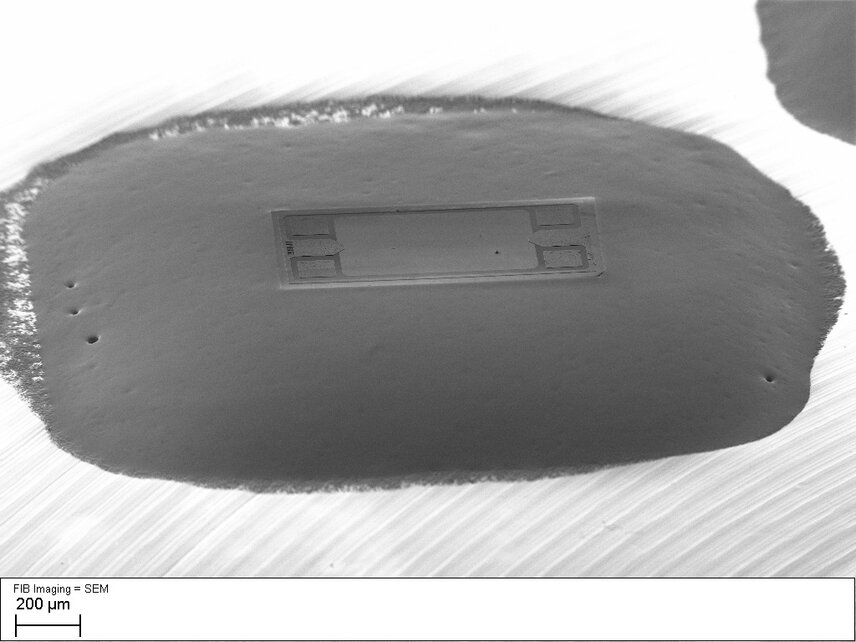

STCC4, one of the world's smallest sensors for direct CO2 measurement, unlocks vast new applications for monitoring CO2 …

Silicon sensor elements based on MEMS technologies offer multiple advantages over conventional sensor technologies in terms of accuracy, long-term stability, …

The internet of tomorrow will be mobile and audio based. To support the shift in communication from typing and reading …