Favorite (7)

Favorite (7)

This call to arms was echoed recently by Dr. David Nabarro, special envoy on Covid-19 for the World Health Organization’s (WHO). In a recent interview he said that a test that delivers results in minutes is essential in order to live with the virus. He added:

“A rapid test that is reliable, that can be used anywhere, is the absolute requirement now, it’s more important than just about anything else and will be a life changer”.

Whilst Dr. Nabarro acknowledged the importance of antibody testing – which can identify whether an individual has recently been infected – he was clear that such tests were not as valuable as a virus test, for diagnosing current infection. One alternative, antigen testing, can detect current infections and like antibody tests is quick and cheap; however, it lacks the sensitivity required. In contrast, molecular diagnostics (MDx) is considered the gold standard for infectious disease testing, with numerous advantages including, sensitivity, accuracy, multiplexing and test range.

Alongside its many advantages, there are however several drawbacks to MDx; the primary being the time to test result. Currently, most testing is carried out in laboratories which means that samples must be collected and sent away for analysis and secondly the Sample Turn Around Time (STAT) in these laboratory systems is relatively long – approximately 30-60 minutes. As a result, many diagnostic companies are looking at new and innovative ways to improve the process; these include testing at Point of Care (POC), and methods of simplifying sample collection and preparation, so that in theory the test could be carried out by the general public rather than a trained ‘swabber’ or clinician. Also, given the volume of testing required, there is a significant drive to reduce the cost per test; so that routine testing can be carried out on the front line, and on a regular basis in day to day settings such as care homes, the workplace and schools.

At the heart of many MDx devices is a microfluidic system, in which small quantities of fluid must be moved accurately and precisely, in a way that delivers a fast and reliable result. Systems designers are constantly looking for new and innovative ways to drive the fluidic system; this is where selecting the right micropump or pumping system is critical. There are many pump options available to designers of POC MDx systems. The following key considerations should factor in the pump selection process:

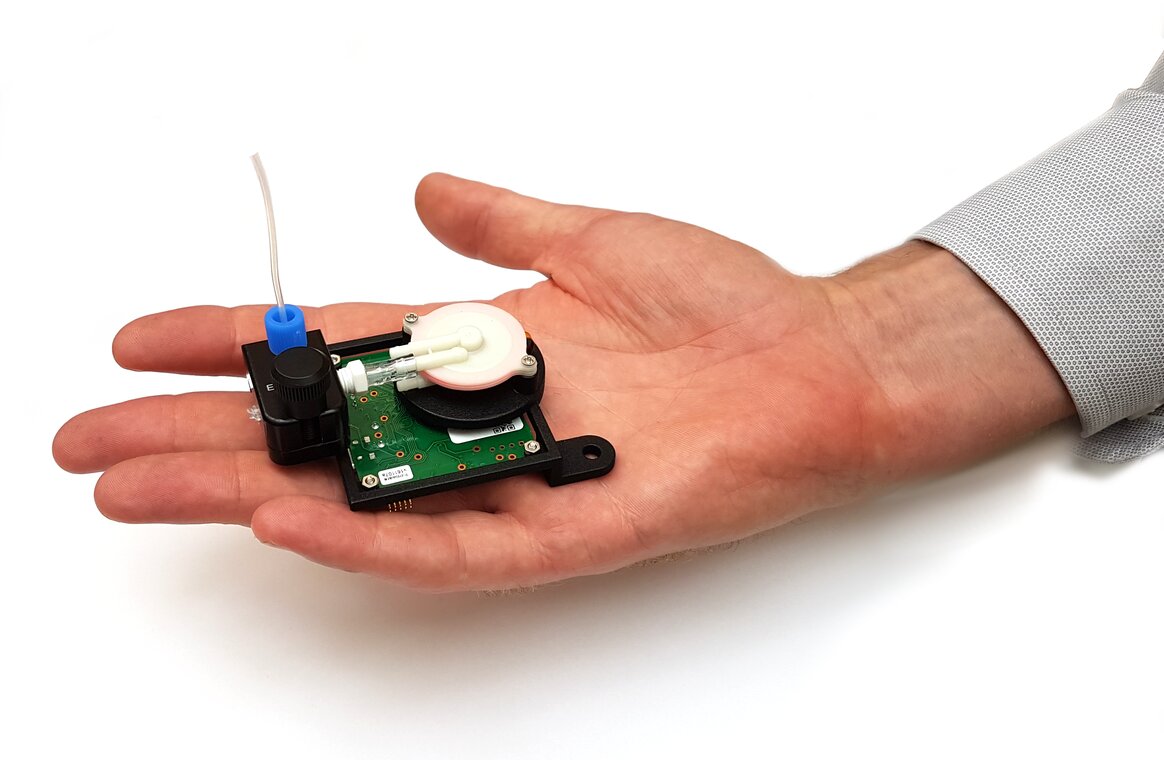

The multi award-winning Disc Pump from TTP Ventus is a novel piezoelectric micropump, with a unique set of attributes that are well-matched to the requirements of many microfluidic circuits and POC diagnostic systems.

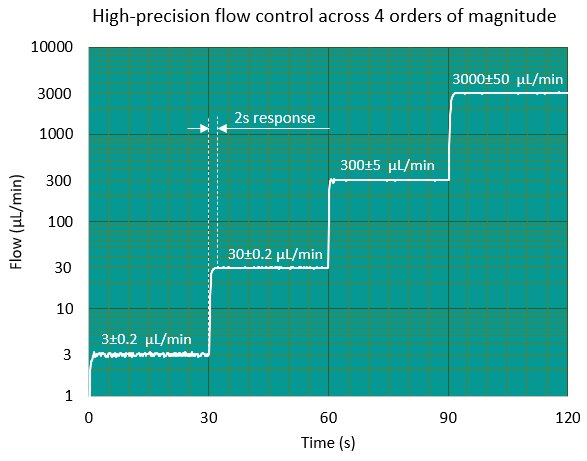

High-precision flow control – Disc Pump offers excellent regulation of gas pressure (and vacuum) – often much better than 0.1 % - which in turn drives stable, accurate and precise liquid flow. Further, unlike conventional pumps, Disc Pump has no stall speed, so that very low pressures – and in turn, very low liquid flow rates – can be delivered. This makes it possible to achieve incredible accuracy across a wide performance range. Figure 2 shows a logarithmic step-function in flow rate over four orders of magnitude: 3, 30, 300 and 3000 μL/min.

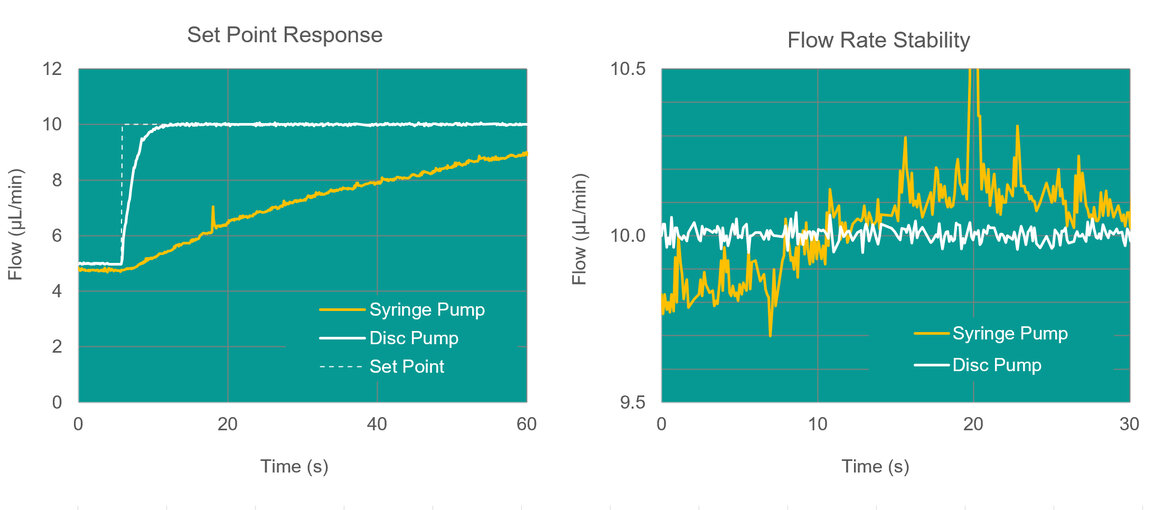

Rapid response speed – microfluidic systems powered by Disc Pump can react to set point changes within a couple of seconds, as contrasted with syringe pumps which can often take minutes to settle at a new set point. Fast response speeds support faster processing (target flow rates are reached more quicky), and a reduction in wastage of precious liquids.

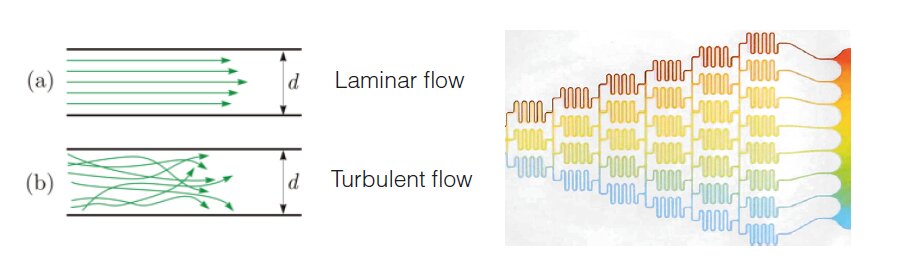

Ultra-smooth flow – Disc pump moves just a few nanolitres of air per cycle and as such the resultant air flow is effectively pulsation free. This allows Disc pump to create stable pressure that drives smooth, laminar liquid flow streams. This helps to maximise system repeatability and stability. Also, pulsation free flow helps to reduce bubble formation and bubble entrainment.

Compact and lightweight – Disc Pump weighs only 5g (< 1/5 oz) and has a volume of just 7 cm3 (<0.5 in3), enabling miniaturisation of the next generation of portable POC systems.

Improved STATs - The fine control and rapid response time also allows designers to push the limits of processing speed. Disc Pump also supports faster processing techniques, such as droplet-digital PCR.

Versatility and reliability – Disc Pump can generate positive and negative pressures with unrivalled precision. In combination with valving, it can be used to move fluids backwards and forwards through microfluidic circuits. The pump can be located off chip (within the instrument), reducing the complexity and cost of the disposable element, in turn reducing the cost per test.

In the fight against COVID-19, there is a clinical need to offer fast, reliable diagnostic solutions at the Point of Care, whilst at the same time reducing the cost per test. The microfluidic systems deployed in these instruments must deliver excellent performance and faster STATs, with a small, lightweight footprint. With its excellent flow control and compact form factor, TTP Ventus’ Disc Pump is well positioned to meet this need. TTP Ventus is committed to sharing our pump expertise in the pursuit of this ambition for widescale testing.

With cross-industry cooperation, we believe that the call to arms from WHO Director General Tedros Adhanom Ghebreyesus will be met and that by innovating together, we can win the fight against the pandemic.